- QINDING

- Shandong,China

- 20 Days

Whether you’re a sheet metal fabricator, automotive technician, roofer, or DIY enthusiast tackling a home renovation, cutting through thin metal sheets, roofing panels, or aluminum siding can be a struggle with ordinary tools. Qinding Aviation Snips are engineered to make this task effortless: featuring precision-forged CR-V steel blades, a labor-saving lever design, and multi-directional cutting capability, they deliver clean, burr-free cuts through 18-gauge steel and 16-gauge aluminum—no more jagged edges or wasted effort.

🛠️ Core Selling Points

Premium CR-V Steel Blades

Forged from high-quality Chrome-Vanadium (CR-V) steel and heat-treated to HRC50-55 hardness, the blades are ultra-sharp, wear-resistant, and stay sharp longer than standard carbon steel alternatives. The precision-matched cutting edges ensure clean, burr-free cuts through metal sheets up to 1.2mm thick.

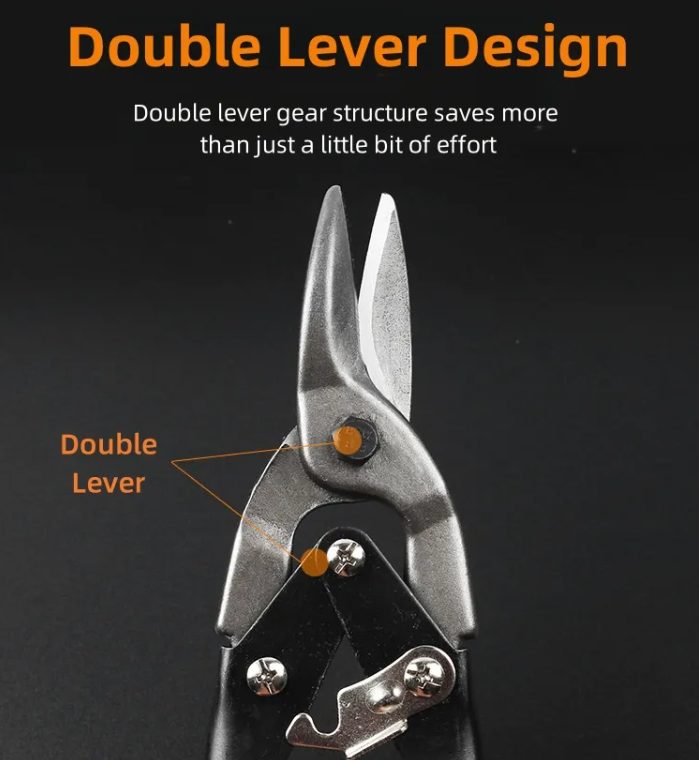

Labor-Saving Lever Mechanism

The 4:1 leverage ratio design reduces cutting force by up to 75%, making it easy to slice through tough metal even with one hand. This ergonomic mechanical advantage minimizes hand fatigue, so you can work longer without strain.

Multi-Directional Cutting Options

Available in three specialized models to suit every task: - Straight Cut: For clean, straight lines in flat metal sheets - Left Cut: For curved cuts to the left (ideal for contouring panels) - Right Cut: For curved cuts to the right (perfect for tight-radius work)

Ergonomic Anti-Slip Handle

The dual-material handle combines soft TPR rubber with durable engineering plastic, featuring a textured grip that stays secure even when wet or greasy. The contoured design fits naturally in your palm, reducing wrist strain during extended use.

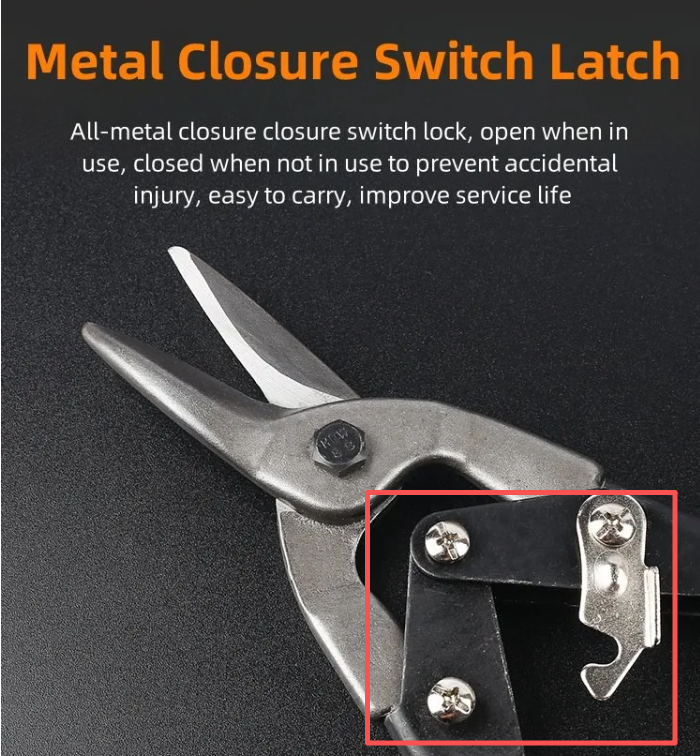

Safety & Durability

Built-in safety lock keeps the blades closed when not in use, preventing accidental cuts and making storage safe. The electrophoretic rust-resistant coating protects against corrosion, ensuring long-lasting performance even in damp or outdoor environments.

📊 Technical Specifications

Parameter | Details |

|---|---|

Blade Material | Chrome-Vanadium Steel (CR-V) |

Surface Treatment | Electrophoretic Coating + Precision Polishing |

Hardness | HRC50-55 |

Cutting Capacity | 18-gauge (1.2mm) cold-rolled steel / 16-gauge (1.6mm) aluminum |

Cutting Direction | Straight / Left / Right (3 models available) |

Handle Material | TPR Soft Rubber + Engineering Plastic |

Size | 10" (250mm) overall length |

Weight | 450g per snip |

Application | Sheet metal fabrication, automotive repair, roofing installation, DIY projects |

🎯 Ideal Scenarios

Sheet Metal Work: Cutting steel/aluminum panels for HVAC systems, ductwork, or industrial enclosures

Automotive Repair: Trimming body panels, cutting rusted metal, or modifying exhaust components

Roofing & Guttering: Cutting metal roofing sheets, flashing, or gutter sections

Home DIY: Building metal furniture, installing decorative metal accents, or crafting garden projects

Construction: Cutting metal studs, framing, or temporary bracing materials

💡 Warm Tips

Choose the correct cut direction (straight/left/right) based on your project needs for optimal results.

Avoid cutting hardened steel or wire thicker than the rated capacity, as this may damage the blades.

Keep blades clean and lubricate the pivot regularly with light machine oil for smooth operation.

Engage the safety lock when storing to prevent accidental injury and protect the blade edge.

Show details

Most Practical and Economical Series: The perfect blend of functionality and affordability.

Drop Forged Chrome Molybdenum Alloy Steel Blades: Serrated edges for precise and effortless cutting.

Induction Hardened Cutting Edges: Achieve 58-62 HRC for unparalleled sharpness and resilience.

Cutting Capacity: Effortlessly cuts up to 1.2mm cold-rolled steel or 0.7mm stainless steel.

Available Blade Finishes: Choose between black oxidized or sand blasted for your specific needs.

🎁 We support OEM/ODM customization, and can adjust the color, logo, and packaging according to your needs.

Our Advantages

1) MOQ : We can supply you the low mini order quantity

2) OEM : We can produce the goods as per the customer requirement.

3) Service : We are much more concern for the ON TIME DELIVERY & QUALITY