It can be used for Bobcat, XCMG, Liugong, Case, Cat, Longong, Sanhe Intelligence and other brands as well as customized crawler slip loaders.

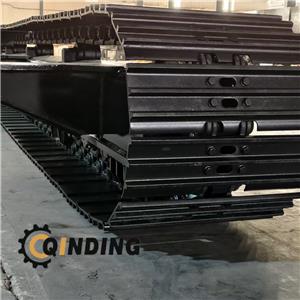

QDRT-03TS Heavy-Duty Triangular Rubber Chassis – Sliding Loader Undercarriage for Construction

It can be used for Bobcat, XCMG, Liugong, Case, Cat, Longong, Sanhe Intelligence and other brands as well as customized crawler slip loaders.

The triangular slewing loader (typically referring to the compact crawler loader CTL or the slewing loader with a triangular track conversion system) combines the flexibility of slewing steering with the high passability of the crawler chassis. Its core advantage lies in the synergy of the "high drive" triangular structure and the rubber tracks.

1. Structural features

Triangular high drive design (High Drive): The drive wheels are located at the top of the triangle, avoiding direct impact from ground debris and stones. This structure separates the load-bearing load from the driving force, protecting the reducer and hydraulic motor.

Rubber track material: Internally, it usually contains high-strength steel wire cord and steel core to ensure tensile strength.

Suspension and support system: The chassis consists of support wheels, guide wheels, and drive wheels. Some high-end models are equipped with a suspension system, which can float according to the terrain and improve operational comfort.

2. Core performance advantages

Extremely low ground contact pressure: The rubber tracks have a much larger contact area than tires, reducing ground pressure by up to 75%. This enables the machine to operate on muddy, sandy, snowy, or delicate lawns without sinking or damaging the ground.

Excellent traction and stability:

Traction: Provides stronger pushing and digging force than wheel loaders on soft ground.

Stability: The lower center of gravity and wide support surface enhance the anti-tilt ability when operating on slopes.

Multi-terrain adaptability: The rubber material reduces vibrations and noise, making it suitable for outdoor construction and also capable of traveling on hard surfaces such as asphalt roads or concrete without damaging the surface.

3. Common track pattern selection

Choosing the appropriate pattern based on the operating environment can extend the lifespan of the chassis:

Block pattern (Block): General type, suitable for paved roads, gravel, and hard soil, with good wear resistance.

C-Lug pattern (C-Lug): Provides excellent grip in mud and soft soil.

Bar pattern (Bar): Causes the least disturbance to the ground and is suitable for delicate landscaping and snow operations.

Zig-Zag pattern (Zig-Zag): Designed specifically for extreme muddy or slippery environments, with strong mud removal capability.

4. Maintenance points

Tension check: Loose tracks can cause "teeth jumping" or derailment, while tight tracks will exacerbate wear and power loss.

Track systems can be used multi-functionally. A track system is constructed for loads of 300 kg to 120,000 kg. Depending on the required load and capacities, you can choose a track system with rubber tracks, a track system with steel tracks or a track system with interchangeable tracks, so that you can switch between rubber and steel. The common features of all track systems are the low soil pressure, the 360° turning possibility and the excellent cross-country manoeuvrability.

Packing:

Drive gear wear: Regularly measure the wear of the drive wheel teeth. When the wear exceeds 75%, replacement is necessary to avoid damaging the track steel core.

Foreign object cleaning: Clean the stones and debris inside the chassis in time to prevent rubber tearing or damage to the guide wheels due to compression.

If you are interested in the product, please feel free to contact us.