excavator undercarriage parts

-

Daewoo Excavator Undercarriage Parts, Sprocket for Daewoo Excavator Solar-220, Solar-225, Solar-230 108.00017

QINDING offers excavator sprocket products in models such as Solar-220, Solar-225, Solar-230 108.00017.They are made of high-quality materials, precisely processed and heat-treated, featuring wear resistance and impact resistance, and boasting a long service life.

Email Details -

Undercarriage Parts Track Roller Bulldozer Bottom Roller D6h D6h XL D6h LGP

QINDING offers bulldozer track roller products in models such as D6h and D6h XL. They feature new-added functions, adopt the specifications for Used wheel loaders, and are of reliable quality.

Email Details -

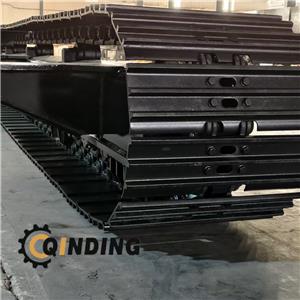

Komatsu Excavator PC200 PC300 PC400 undercarriage parts of track link with shoes

Qinding Machinery specialize in providing undercarriage parts for Excavator and Bulldozer, The brand include Caterpillar, Komatsu, Volvo, Hitachi, Doosan, Daewoo, Shantui and other well-known brand.

Email Details -

YMMA Excavator Undercarriage Parts YM55 TOP Roller

YMMA Excavator Undercarriage Parts YM55 TOP Roller Quality of our products are high at reasonable prices, certified by ISO9001:2008, specifically designed, engineered and manufactured under consistent quality control. We also make according to OEM requirements. What’s more, we can produce new products according to customers’ supplied samples, designs or technical drawings.

Email Details -

Undercarriage Parts For ATLAS Crawlerdrill

Undercarriage Parts For ATLAS Crawlerdrill Main Features 1. Sta1. Standard product design 2. High quality material selection 3. Advanced imported manufacture & testing equipment 4. Advanced manifacturing process and production technology 5. in the line with global standards 6. By long time testing, proved to be good conditionndard product design"

Email Details -

Bottom Roller For Doosan DX220 Excavator Undercarriage Parts

Bottom Roller For Doosan DX220 Excavator Undercarriage Parts • Bottom roller are forged, quenched and tempered. • Rail deep hardened, with average surface hardness HRC 53. • Track bushings treated in a special furnace for high temperature carburizing. • Deep hardened pins for best resistance to wear and fatigue. • Track shoes heat treated for proper toughness and wear resistance.

Email Details