Qinding Machinery successfully delivered a 1.6-ton custom-made steel track frame

Qinding Machinery successfully delivered a 1.6-ton custom-made steel track frame

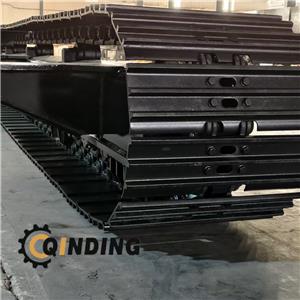

Recently, relying on its technical accumulation and flexible manufacturing capabilities in the crawler chassis field, Qinding Machinery successfully customized and delivered a 1.6-ton steel track frame for a customer. This product accurately meets the customer's specific operating scenario requirements, and has won high recognition from the customer with its excellent performance and reliable quality, providing a customized solution for the upgrading of small equipment in fields such as construction machinery and mineral exploration.

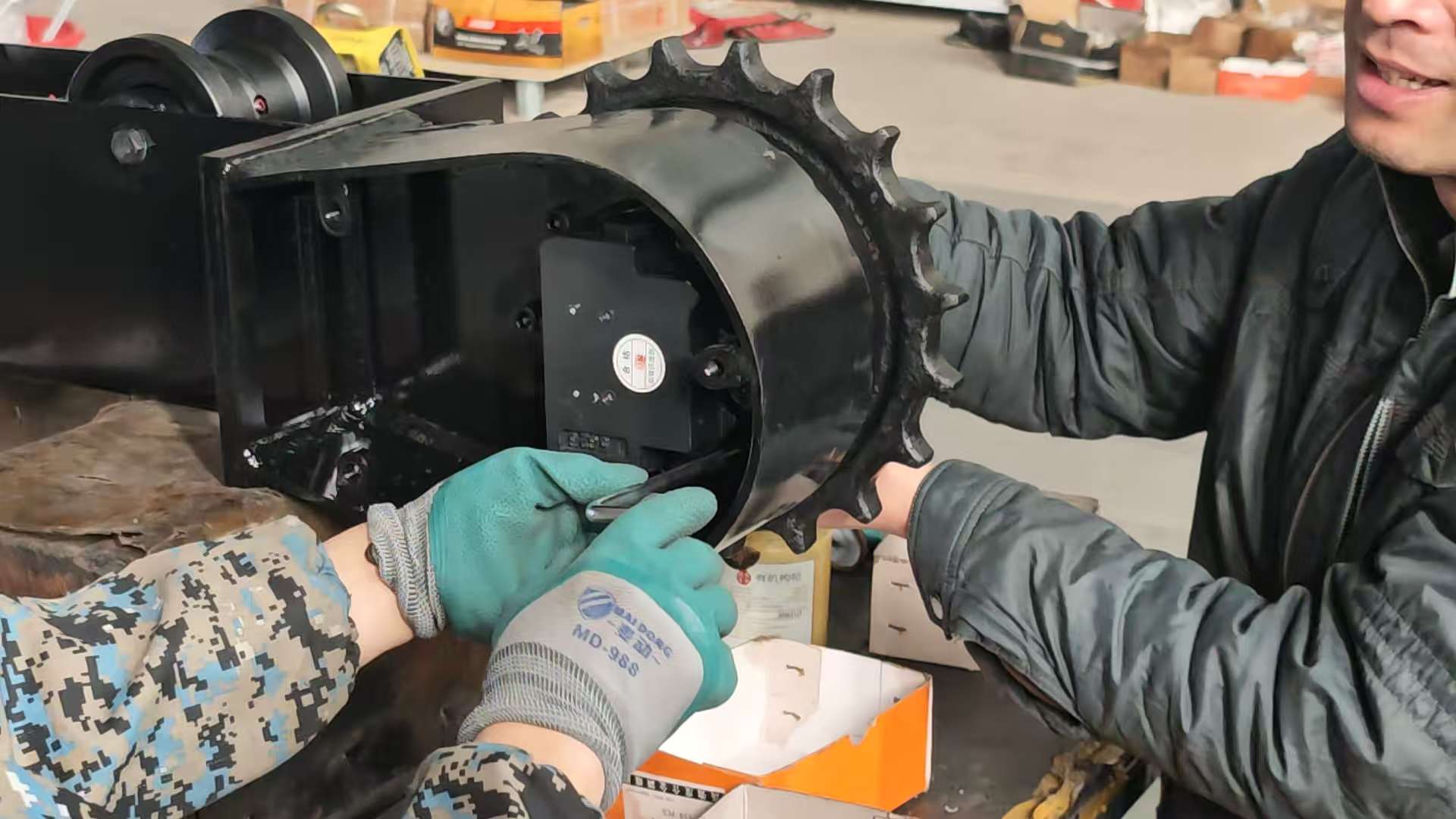

To achieve precise adaptation, the R&D team of Qinding Machinery conducted multiple rounds of demand docking with the customer, in-depth analysis of the terrain characteristics, load requirements and equipment compatibility of the operating scenario, and optimally arranged the driving wheel, idler wheel and carrier roller in a targeted manner. It integrates a fully floating carrier roller set and a hydraulic tensioning device, which reduces the ground contact pressure of the equipment, significantly improves the steering flexibility, and the climbing capacity can reach more than 25°, maintaining stable operation even in narrow spaces and complex road conditions. At the same time, the frame adopts a double-sealed shaft end structure, which effectively prevents lubricating oil leakage and muddy water from invading the wheel cavity, reduces later maintenance costs and extends the service life of the equipment.

As an enterprise specializing in the R&D and manufacturing of crawler chassis and core components, Qinding Machinery has the full-series customization capability of 1-120 ton steel crawler chassis, and its products are widely suitable for various equipment such as excavators, drilling rigs, aerial work platforms and agricultural machinery. Adhering to the concept of "customer demand-oriented", the company has built a full-cycle customized service system from demand research, scheme design, precision manufacturing to delivery and operation and maintenance. Relying on the intelligent production base and professional technical team, it can quickly respond to customers' personalized needs and realize efficient mass production and quality control of customized products.

Qinding Machinery sincerely welcomes customers at home and abroad to cooperate with us. Whether it is customization of specific tonnage, working condition adaptation or functional characteristics, we will create exclusive solutions with ingenuity and precision, empower industrial upgrading with reliable products and high-quality services, and build a win-win ecosystem together.