Qinding Machinery Empowers the High-End Heavy-Duty Engineering Field

Qinding Machinery Empowers the High-End Heavy-Duty Engineering Field

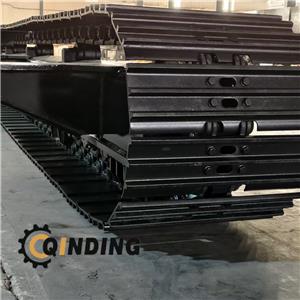

Recently, relying on years of technical accumulation and process innovation in the crawler chassis field, Qinding Machinery has successfully achieved large-scale mass production of the 27-ton load-bearing steel track chassis. Tailor-made for ultra-heavy-load operation scenarios, this product has achieved multiple breakthroughs in structural strength, load-bearing stability and adaptability to complex working conditions. It can be widely used with core equipment such as medium-sized excavators, heavy-duty crawler cranes and large drilling equipment, providing reliable core component support for high-end heavy-load projects such as mining and large-scale infrastructure, and further improving Qinding Machinery's full-series crawler chassis product matrix covering 1-120 tons.

As a benchmark product in Qinding Machinery's heavy-load series, the 27-ton steel track chassis adopts the core design concept of "ultra-load-bearing, impact-resistant and high-durability", fully complying with the requirements of the JB/T 2602-2016 industry standard. It also takes into account the appearance texture and transportation protection, focusing on optimizing customized spray painting and packaging services to accurately match the diverse needs of customers. The main body of the chassis is made of low-alloy high-strength alloy steel with a tensile strength of not less than 800MPa, which can stably bear 27 tons of rated load and instantaneous impact load, completely solving the industry problem of easy deformation and excessive wear of the chassis under heavy-load conditions. At the same time, it is equipped with customized exquisite spray painting services, comprehensively balancing protection and aesthetics.

Relying on a complete production system and strict testing standards, Qinding Machinery has realized the efficient mass production, quality control and refined service implementation of this chassis model. Before each chassis rolls off the production line, it undergoes strict multiple performance tests and comprehensive quality verification to fully ensure reliable product performance and qualified quality, meeting the strict requirements of high-end heavy-load projects; at the same time, the adhesion and wear resistance of customized spray painting are sampled and inspected, and the compression resistance and moisture-proof performance of packaged finished products are tested to comprehensively ensure product quality and transportation safety. At present, this product has been successfully applied to a large copper mine mining project in Yunnan and multiple large bridge pile foundation construction projects, and its reliable performance, exquisite customized spray painting and thoughtful packaging services have won high recognition from customers, showing strong market competitiveness.

Adhering to the concept of "customer demand-oriented and technological innovation as the core", Qinding Machinery has been deeply engaged in the R&D and manufacturing of crawler chassis, and its products are widely used in mining, construction, infrastructure, special equipment and other fields. The mass production of the 27-ton steel track chassis this time marks the further improvement of the company's technical strength and production capacity in the field of heavy-load crawler chassis. In the future, Qinding Machinery will continue to focus on the demand pain points in the heavy-load engineering field, continuously optimize product performance, improve the full-series product matrix, and provide customized solutions and full-life cycle services. We sincerely welcome customers at home and abroad to cooperate with us to build a new blueprint for the development of heavy-load projects.