Qinding Machinery 8-ton Steel Track Chassis - Modular Assembly Empowers Diverse Medium and Small Working Conditions

Qinding Machinery 8-ton Steel Track Chassis - Modular Assembly Empowers Diverse Medium and Small Working Conditions

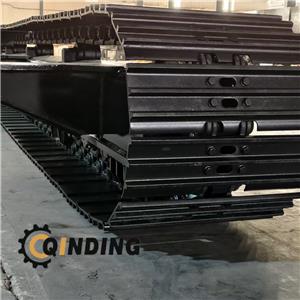

As a core product in Qinding Machinery's medium and small-sized crawler chassis lineup, the 8-ton steel track chassis has become a preferred supporting component for equipment such as excavators, exploration drilling rigs, and small aerial work platforms, thanks to its flexible adaptability and efficient assembly.

Compared with heavy-duty chassis, this model focuses more on modular design and precise matching of working conditions in assembly, adhering to the core principle of "lightweight without compromising quality" to maximize operational value in multiple scenarios.

In the assembly process, Qinding Machinery adopts a modular strategy of "zonal prefabrication + precise splicing", significantly improving assembly efficiency and consistency. The main body of the track frame is formed by CNC bending of high-strength alloy steel, and the box beam structure is prefabricated and welded in advance, with strict control of dimensional tolerance to ensure assembly accuracy, then modularly connected with the carrier roller set and drive system. Both the carrier roller and idler wheel adopt deep groove ball bearing design, with special grease injected once during assembly, combined with a double-sealed shaft end structure, fundamentally preventing muddy water intrusion and lubricating oil leakage, suitable for maintenance-free needs of various medium and small scenarios such as orchard operation, small tunnel construction and garden renovation.

To meet the diverse needs of medium and small working conditions, customized interfaces are reserved during assembly, allowing adjustment of track plate width (adapting to 400-600mm specifications) and tensioning mechanism parameters according to customer equipment types. The spring tensioning mechanism adopts a screw adjustment design, with precise calibration of tension value during assembly to ensure stable track operation, while improving the steering flexibility of the equipment in narrow spaces and gentle slope terrain. In addition, digital inspection is integrated throughout the assembly of this chassis model, and each finished product must pass three links: no-load test run, load test and sealing performance test, widely suitable for multiple scenarios such as shallow mineral exploration, municipal pipeline laying and small farmland water conservancy construction.