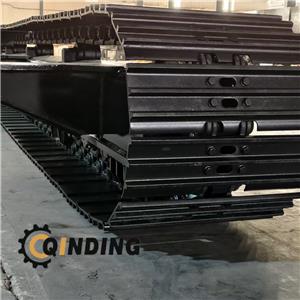

Qinding Machinery 12-ton Steel Track Chassis - Heavy-load Oriented Assembly Lays a Solid Foundation for Medium and Heavy-duty Operations

Qinding Machinery 12-ton Steel Track Chassis - Heavy-load Oriented Assembly Lays a Solid Foundation for Medium and Heavy-duty Operations

Targeting medium and heavy-duty operation scenarios such as mine stripping mining, large-scale infrastructure foundation pit excavation, and port bulk cargo transfer, Qinding Machinery's 12-ton steel track chassis takes "heavy-load resistance, stability and reliability" as the core. Through targeted assembly process optimization and enhanced design, it builds an operational foundation with both load-bearing strength and operational stability. Compared with the 8-ton model, its assembly focuses on structural reinforcement, power matching and precision control under heavy-load conditions, and can be used with medium-sized excavators, crawler cranes and large drilling equipment, demonstrating strong manufacturing capabilities.

In the assembly process, the primary task is to break through the heavy-load bearing bottleneck: the track frame adopts thickened web and dense stiffener welding technology, and the welds are inspected by ultrasonic flaw detection with a pass rate of 100%, effectively improving overall rigidity and deformation resistance. The teeth of the driving wheel and idler wheel are made of high-strength alloy steel through integral quenching treatment, with surface hardness increased to above HRC55. During assembly, the meshing clearance of the wheel system is precisely adjusted to ensure efficient power transmission and uniform wear. At the same time, it is equipped with a built-in low-speed and high-torque motor travel reducer, which is accurately connected with the track drive system during assembly to achieve strong traction and high trafficability under heavy-load conditions.

For the harsh environment of medium and heavy-duty operations, detailed protection and precise commissioning are strengthened during assembly. The carrier roller set adopts a fully floating layout, and the ground contact pressure is strictly calibrated during assembly to ensure uniform force on the equipment in complex terrains such as mud, gravel and rock piles; the hydraulic tensioning mechanism replaces the traditional screw adjustment, which can dynamically adjust the track tension according to the operation load, reducing the damage to the chassis caused by heavy-load impact. After the assembly of each chassis, it must undergo 72-hour continuous heavy-load test run and extreme working condition simulation test to fully verify the load-bearing capacity, sealing performance and operational stability, providing reliable support for medium and heavy-duty projects such as open-pit mining, bridge pile foundation construction and large wind power equipment installation.

Flexible production adapts to diverse needs, precision manufacturing shows strong strength—we go all out for your customization requirements.