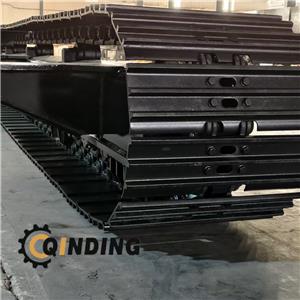

Customized-galvanized-crawler-beam

Qinding Machinery: Customized galvanized crawler beam

"Always keep customers in mind, make product quality excellent, and provide good service" — this is the unchanging original aspiration and core commitment of Qinding Machinery after years of deep cultivation in the construction machinery field.

Recently, Qinding Machinery, a professional R&D and manufacturing enterprise of core construction machinery components, officially launched customized galvanized track beams. This product specifically addresses the industry pain points of track beams such as easy corrosion, short service life and high maintenance costs under harsh working conditions. With customized adaptability and advanced galvanizing technology, it provides long-term protection solutions for various tracked equipment including excavators, bulldozers and crawler cranes.

Keeping customers in mind is reflected in the customized ability to accurately meet needs. Qinding Machinery has set up a professional technical team to take the initiative to go deep into customer operation scenarios and provide full-process customized services based on multi-dimensional information such as equipment models, operation intensity, and environmental characteristics. Whether it is the precise matching of key dimensions such as drive wheel mounting seats and track roller tracks, the customization of high-strength base materials for special needs such as heavy loads and high-frequency impacts, or the personalized deployment of special coatings resistant to acid rain and marine climate, it can accurately meet the differentiated needs of customers, making the product perfectly fit the actual operation needs of customers.

Providing good service runs through every link of the entire product life cycle. Qinding Machinery has built a full-chain service system from pre-consultation, scheme design, to production follow-up, delivery and acceptance, and after-sales support. In the early stage, technical personnel communicate with customers one-on-one, build product prototypes through 3D modeling software, and share design schemes in real time for repeated optimization; during the production process, customers can check the production progress and quality inspection data in real time through exclusive channels to achieve transparent management and control; at the time of delivery, a complete set of technical documents are provided simultaneously, including processing drawings, quality inspection reports, and maintenance instructions, to facilitate customers' subsequent assembly and maintenance; in the after-sales stage, a 24-hour response hotline is set up. If there is an assembly adaptation problem, technical personnel can conduct on-site commissioning; if there is a non-human-induced quality problem during the warranty period, free maintenance or replacement services are provided, truly allowing customers to "feel at ease when entrusting and satisfied when delivering".

The person in charge of Qinding Machinery said: "Customer needs are the driving force for our innovation, product quality is the foundation of our foothold, and high-quality service is the bridge connecting us with customers. The launch of this customized galvanized track beam is a vivid practice of our 'three hearts' philosophy. In the future, we will continue to adhere to our original aspiration, deepen the research and development of core components of crawler chassis, and help customers reduce operating costs, improve operation efficiency, and achieve mutual benefit and win-win results with better products and more intimate services."

At present, Qinding Machinery's customized galvanized track beams have completed adaptation tests for multiple models, and are widely applicable to various harsh operating scenarios such as mining, port loading and unloading, and municipal infrastructure. Relevant customized services have been fully opened. Customers can consult and connect us to experience exclusive customized solutions and worry-free full-cycle services.