Customization Process of Steel Track Chassis by Qinding Machinery

Customization Process of Steel Track Chassis by Qinding Machinery

Qinding Machinery adheres to a customer-centric approach and has established a systematic and standardized customization process for steel track chassis, ensuring that each link is closely linked and efficiently operated to accurately meet the personalized needs of customers in different industries. The detailed process is as follows:

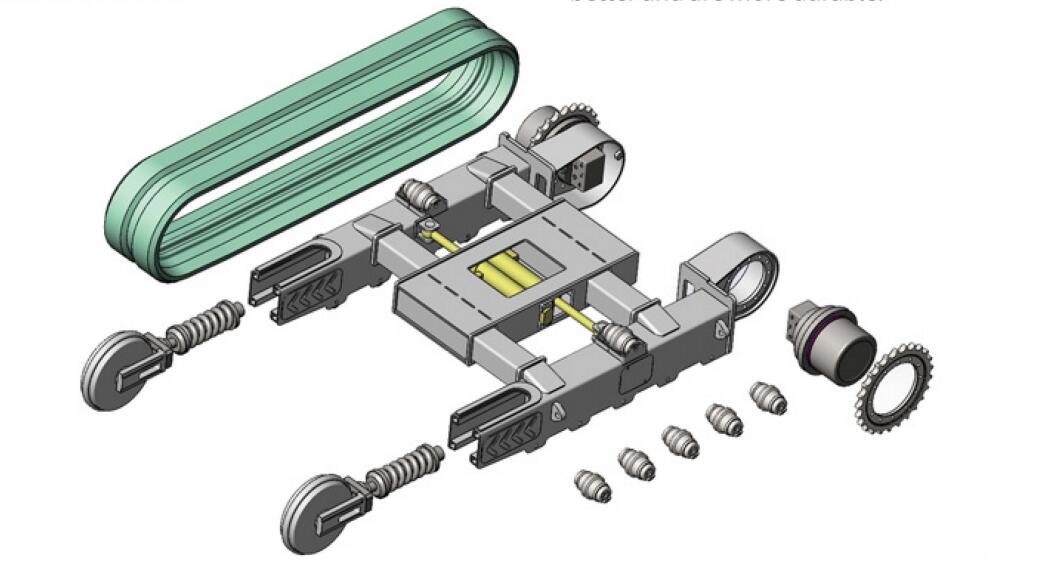

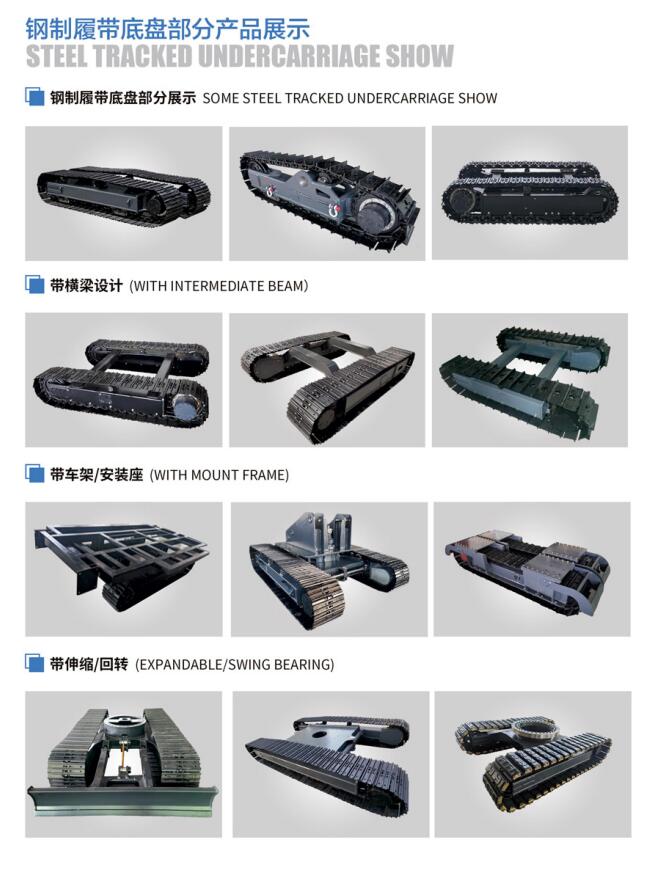

Structural Composition

Tracked Undercarriage Component:

Track Roller

Carrier Roller

Sprocket

Idler

Track Shoe Group/Rubber Track

Travel Motor & Gearbox

Metal Frame

1. Demand Communication & On-site Investigation

The professional technical and sales team of Qinding Machinery takes the lead in conducting in-depth communication with customers. We focus on clarifying core requirements such as the application scenarios (e.g., mountainous areas, mines, swamps), load-bearing capacity, traction requirements, and special environmental adaptability (e.g., high temperature, corrosion resistance) of the steel track chassis. For complex working conditions, we will arrange on-site investigations to simulate the actual operation environment, collect first-hand data, and convert customer needs into clear technical indicators, laying a solid foundation for the subsequent customization work.

2. Scheme Design & Simulation Verification

Based on the confirmed demand indicators, the R&D team carries out systematic scheme design. Using advanced CAD software, we build three-dimensional models of the steel track chassis, and flexibly adjust parameters such as chassis size, structure type, and drive mode (hydraulic/electric). To ensure the reliability and stability of the design, we conduct finite element analysis (FEA) on key components such as the walking frame and track roller to simulate stress concentration and optimize the layout of reinforcing ribs. Meanwhile, compatibility verification is carried out with the customer's main engine equipment to ensure perfect matching.

3. Material Selection & Process Determination

According to the design scheme and actual working conditions, we select high-quality materials scientifically. For example, high-strength alloy steel (such as 40Mn2) is adopted for key components like track links, and wear-resistant alloy steel plates (such as NM400/500) are used for track plates in mining scenarios, with optional tungsten carbide overlay welding to enhance wear resistance. We determine the most suitable manufacturing processes, including precision welding, quenching heat treatment, and anti-corrosion coating. A detailed process plan is formulated and submitted to the customer for confirmation to ensure transparency and consistency of the production process.

4. Precision Manufacturing & Strict Quality Control

After the customer approves the process plan, we start formal production. The manufacturing process strictly follows the established technical standards, with precision welding (such as submerged arc welding and laser welding) ensuring the strength of the chassis structure, and professional heat treatment processes guaranteeing the hardness and toughness of components. Throughout the production process, we implement multi-link quality inspection, including raw material incoming inspection, in-process dimension detection, and flaw detection (magnetic particle testing, ultrasonic testing) of key components. We also conduct load-bearing and wear resistance tests on the finished chassis to ensure that all performance indicators meet the design requirements.

5. Delivery, Commissioning & After-sales Support

After the quality inspection is qualified, we arrange safe and efficient logistics and transportation to deliver the customized steel track chassis to the customer on schedule. Professional technicians are dispatched to the customer's site for installation and commissioning, testing the operation status of the chassis and making fine adjustments if necessary. We provide the customer with detailed product manuals and operation training to ensure that the relevant personnel are proficient in using and maintaining the equipment. In addition, we establish a long-term after-sales service mechanism, providing timely technical support and spare parts supply to solve any problems encountered by customers in the use process.

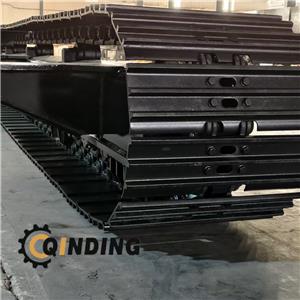

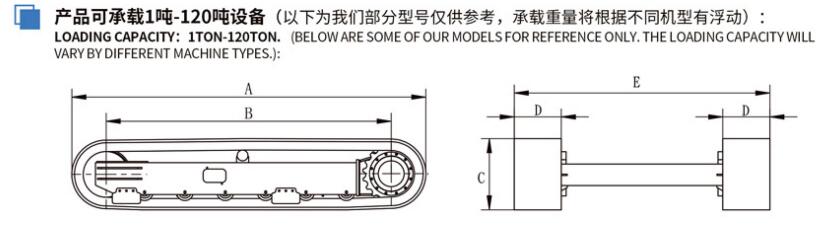

Steel Track Undercarriage

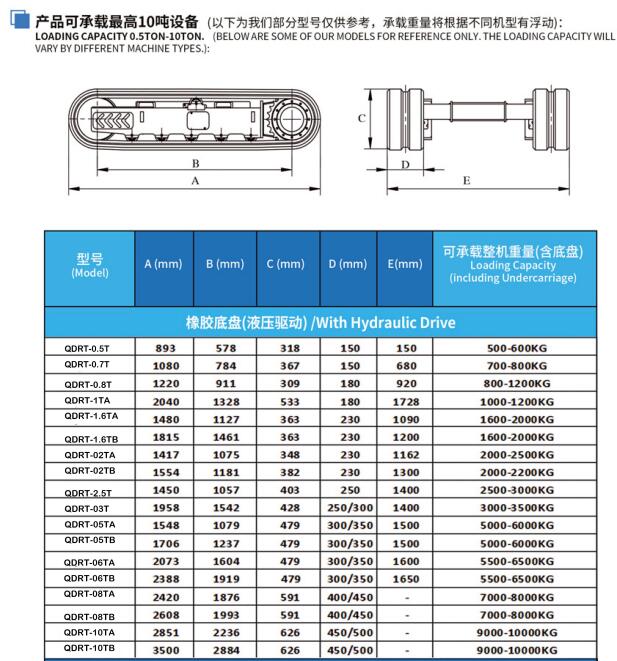

Rubber Track Undercarriage